Commercial Embroidery Machines: What You Need to Know Before Buying

Choosing the right commercial embroidery machine can make or break your shop’s success. Whether you're outfitting a new workspace or upgrading from a...

3 min read

Avery Threadwell : Oct 9, 2025 10:28:20 AM

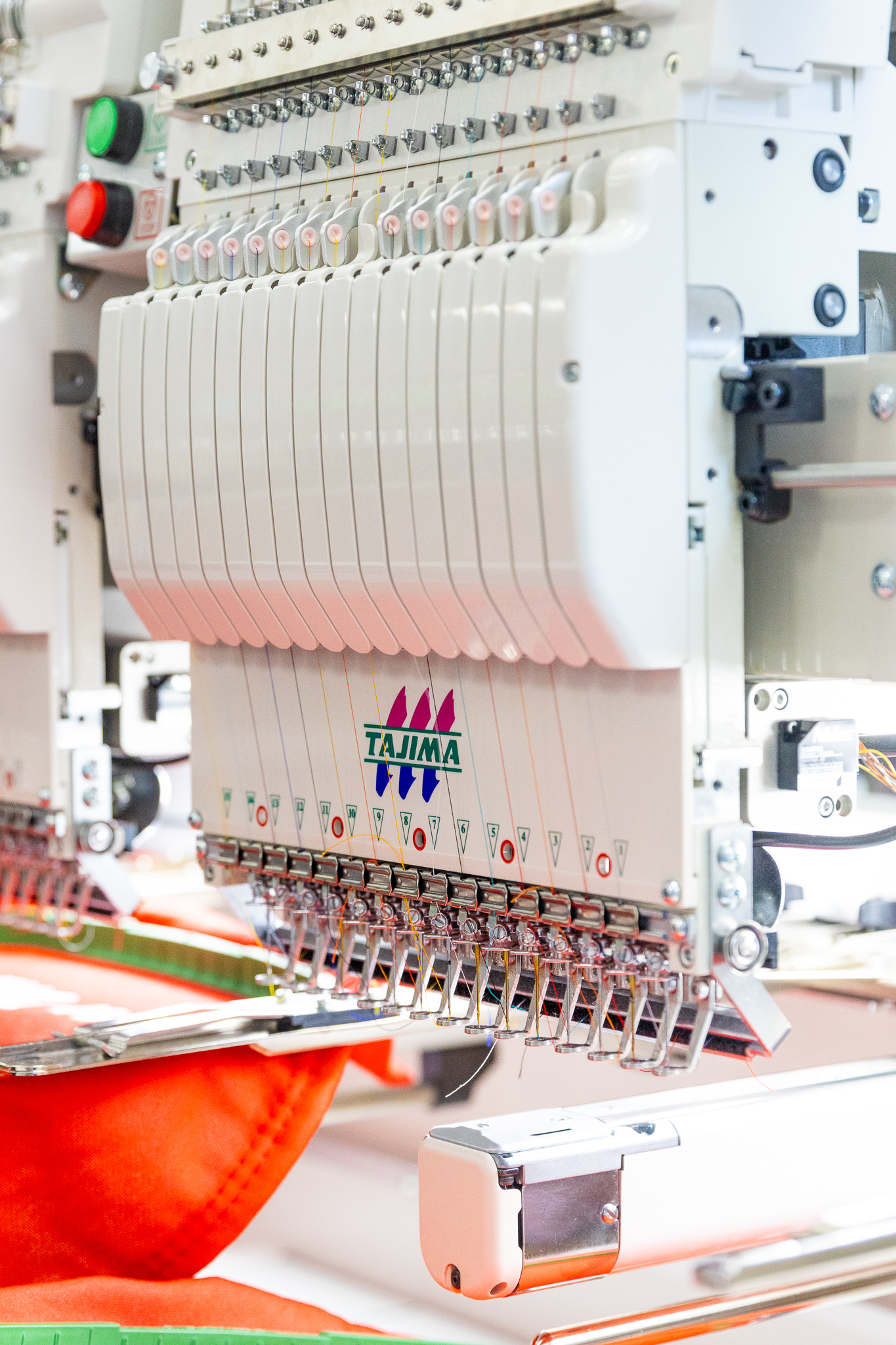

Tajima’s roots go back to 1944, when Ryo Tajima founded an industrial sewing machine sales company in Aichi, Japan.

In 1964, Tajima made a pivotal leap: they developed and released their first multi-head automatic embroidery machine. That machine was the TM-J106—a jacquard type, multi-head machine that marked Tajima's transition from distributor to manufacturer.

The goal was clear: to solve customer needs for faster, consistent and more efficient embroidery production. The TM-J106 allowed multiple heads to stitch the same design, greatly increasing output while maintaining quality. This was a game-changer for apparel decorators, uniform makers, and fashion brands.

Read about how a shop in Denver, CO increased it's production by adding Tajima Multi-head machines ➡️ READ HERE

Engineering Breakthrough: The TM-J106 was not just about adding more heads—it involved precise mechanical control, frame synchronization, and durable construction to ensure all heads delivered uniform stitch quality.

Scale & Efficiency: With multiple heads working simultaneously, shops could produce several copies of the same embroidery design in one run—reducing time, inventory, and labor per piece.

Setting the Stage: The innovation in TM-J106 laid foundation for future Tajima developments—color-change automations, jump mechanism (1970), and multi-color machines with electronic thread change.

Since the TM-J106, Tajima has continuously innovated, building on the multi-head concept:

Jump Mechanism (1970) enabled heads to "jump" without stopping the carriage, improving speed and productivity.

Introduction of multi-color automatic thread changing machines (such as the TMB and TMBE series) expanded possibilities for design without manual intervention.

Further advances: sequin and chenille multi-head machines; lock-stitch variations; electronic heads; automatic tension systems.

Recent flagship models like the TMEZ-KC series incorporate AI-driven features (i-TM, DCP etc.) that automatically adjust thread tension and presser foot pressure—technologies made possible because of decades of engineering that began with early machines like TM-J106.

During our excursion:

We viewed the TM-J106 preserved as a milestone piece—a reminder of Tajima’s early commitment to solving production challenges.

We saw how current machines (like multi-head models with jump mechanisms) have refined the core architecture introduced with the TM-J106: durable frame, synchronized heads, reliable motion controls.

We spoke with engineers about how Tajima preserves customer feedback in their R&D—something that started with those first machines. The same mindset that created the TM-J106 still animates their newest releases.

Even though TM-J106 is a legacy machine, its influence matters:

It establishes the baseline expectations of multi-head uniformity and scalable output. If you are buying a new multi-head machine, you want consistent results from all heads—exactly what the TM-J106 first demanded.

It set the standard for operator usability, frame control, and machine reliability—areas you should still evaluate today when comparing Tajima's TMEZ, TMBP, or any multi-head offering.

Tajima, after building the TM-J106, went on to establish full manufacture and sales of multi-head automatic machines in 1964.

Since then, Tajima has produced over 3,000 embroidery machine models serving over 160 countries and regions. Their product line spans from single-head to machines with dozens of heads.

Tajima isn’t just about hardware: their services, software, innovations (like AI in the TMEZ line) reflect their long-term vision of blending artistry with engineering.

When evaluating embroidery equipment today, here’s what the TM-J106 teaches us:

| What to look for | Why it mattered in TM-J106 | Why it matters now |

|---|---|---|

| Head synchronization & stability | TM-J106 needed precise motion to run multiple heads identically. | In multi-head machines today, consistency across all heads under load is essential for apparel shops. |

| Frame control & durable construction | Early mechanical engineering set the build standards. | Less vibration, long lifespan, fewer breakdowns—even when running high volumes. |

| Innovation tuned to customer feedback | The development from sewing-sales to multi-head manufacturer was driven by user needs. | Modern Tajima features like i-TM come from years of listening to shop pain points. |

| Scalability | TM-J106 showed that doing more (more heads) could scale production efficiently. |

As your business grows, being able to step up to 4, 6, 8-head (or more) machines with minimized learning curve matters. |

Seeing the TM-J106 during our visit was a powerful reminder: every great innovation has humble beginnings. Tajima’s early work with multi-head embroidery machines started in an era of manual operation, trial and error, and engineering courage. Today’s Tajima machines, from the TM-J106’s legacy to the ultra-modern TMEZ, carry forward those principles of consistency, scalability, and value.

If you're considering investing in your next embroidery machine—single-head or multi-head—ask whether it honors the legacy of the TM-J106: synchronization, durability, and innovation that serves your business in the long run. At Hirsch Solutions, we’re here to help connect you with Tajima machines that do just that.

👉 Contact Hirsch Solutions to learn more about Tajima’s multi-head line and find the right machine for your production goals.

800-394-4426 WWW.HSI.US CARE@HSI.US

Choosing the right commercial embroidery machine can make or break your shop’s success. Whether you're outfitting a new workspace or upgrading from a...

When it comes to professional embroidery, there’s one name that consistently rises to the top— Tajima. Known for its precision engineering,...