Print with Speed

Print with Speed

The quicker you get products to market, the sooner you can start turning a profit. The GTX Pro gives you the power to produce prints faster than ever before, giving you a distinct competitive advantage.

Print with Precision

Print with Precision

Never sacrifice print quality for output speed. With a print resolution of 1200 x 1200 dpi combined with cutting-edge Innobella inks, your designs can incorporate the entire color spectrum and even minute details will print with fantastic clarity.

Print in One Pass

Print in One Pass

With the white ink channels stacked right behind the CMYK channels, you can print almost anything in a single pass.

Print with Simplicity

Print with Simplicity

Being easy to use and maintain is one of the most important features of the GTX Pro. The improved wet capping station minimizes clogged nozzles and the white ink circulation system keeps the system primed and ready to print.

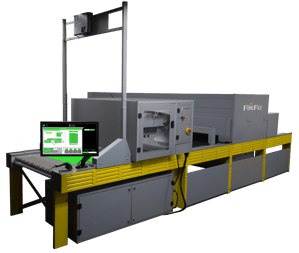

Brother GTX Pro: The hybrid printer designed for versatility, built for reliability.

Since 2005, Brother has been known for making garment printers designed from the ground up. We manufacture our own firmware, software and print heads. Coupled with our specially formulated inks and advanced features, the GTXpro hybrid DTG/DTF printer provides a powerful tool to help you to grow your business.

Print Practically Anywhere

Print Practically Anywhere

The GTX Pro is more than a t-shirt printer. The large gap between the print head and the substrate means you can easily print over seams, across zippers and on top of pockets.

Print Larger

Print Larger

The GTX Pro has the largest print area of any Brother DTG printer ever. With a maximum print size of 16” x 21”, your designs can be bigger and bolder than ever. Extra thick items are no problem thanks to the adjustable platen height system.

Print Safely

Print Safely

The Innobella Textile inks used by the GTX Pro are water-based pigment inks that are Okeo-Tex Eco-Pass certified and CPSIA compliant. The innovative packaging uses less plastic thanks to the new replaceable pouches so there is less impact on the environment.

Print with Confidence

Print with Confidence

When you print and fully cure an item using the GTX Pro and Innobella Inks, you can be sure of its durability and washability. That’s because Innobella Textile inks have scored 4.0 or higher on AATCC wash tests.

Specifications

Printing Method - Direct inkjet garment printer

Printing Applications - Direct to garment and direct to film printing

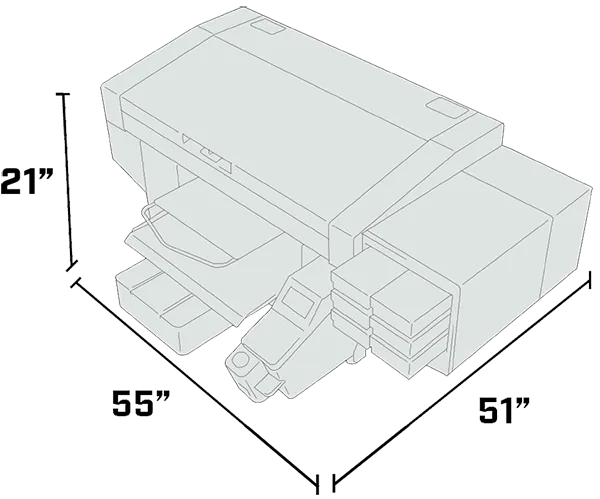

Machine Size - 55”(W) x 51”(D) x 21.7”(H) (1400mm x 1300mm x 550mm)

Machine Weight - 265lb (approx.120kg) including platen; not including the stand

Included Platen Size - Adult Platen - 14“ x 16“ / 35,6cm x 40,6cm

Ink Type - Water-based pigment ink

Ink-Head Type - On demand piezo head

Number of Ink-Heads - 2 print heads / 8 ink channels

Print Resolution - 1200 dpi x 1200 dpi

Print Mode - Single or double for CMYK. Underbase and highlight for white.

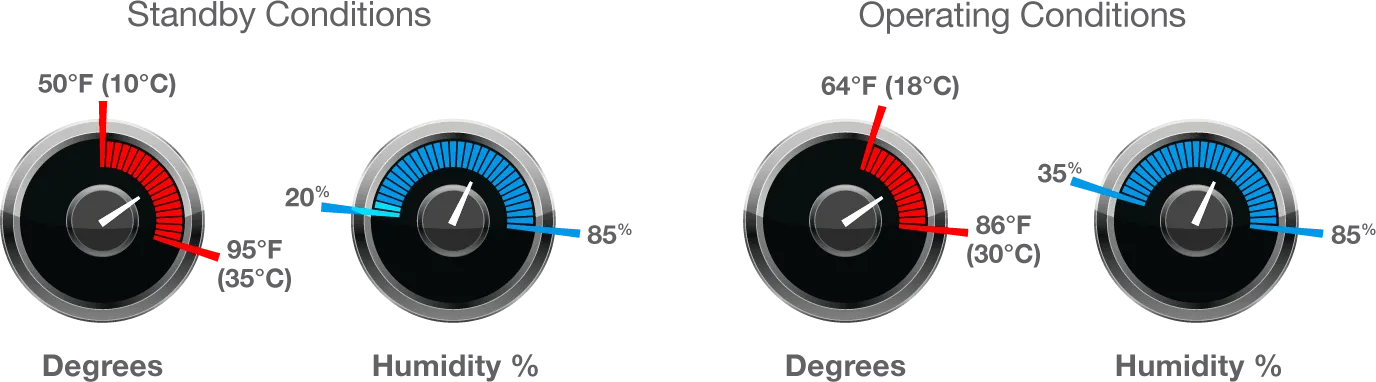

Environment

Data output - Printer driver (USB, File output, LAN)

Power supply - AC 100V-240V, 50/60Hz ± 1Hz

Power consumption - 0.8A(average) (Reference: 0.3A - during circulation)

Ink cure - Heat press machine can be used at 356°F (180°C) and 35 seconds duration. For higher volume production, a conveyor oven is recommended to be used at 320° (160°) for three and a half minutes. Time and temperature may vary depending on which manufacturer's dryer is used.

Pre-treatment

Before printing, apply pre-treatment using either a manual or automatic device and then dry garment using a heat-press, being sure to follow all manufacturer's instructions. Pre-treatment is necessary for white ink.

Software

macOS® Big Sur to macOS® Ventura, Windows 8.1 (64-bit), Windows 10 (64-bit) and Windows 11 (64-bit)

macOS® Big Sur to macOS® Ventura, Windows 8.1 (64-bit), Windows 10 (64-bit) and Windows 11 (64-bit)

Interface - USB2.0, LAN(10BASE-T, 100BASE-TX, 1000BASE-T), USB Flash Memory(Under 32GB, FAT32 format)

Driver operating conditions - 2GHz CPU (minimum recommendation), 4GB RAM

Display resolution - XGA(1024x768) (minimum recommendation)

Recommended applications -CorelDRAW® 2018/2019 (Windows), Adobe® Photoshop CS6/CC, Adobe® Illustrator CS6/CC

Bring your prints to the Pro Level

The GTXPro Direct to Garment printer puts more features, more flexibility, and more capabilities into your bag of printing and decorating tricks. It works harder for you, so you can work harder on growing your business and tapping into new markets.

-1.png?width=677&height=451&name=GTX%20Pro%20with%20Aux%20Equipment%20(1)-1.png)

.png?width=2060&height=582&name=Hirsch%20(%20justified).png)

%20wht.png?width=2060&height=582&name=Hirsch%20logo%20(justified)%20wht.png)

.gif?width=400&height=251&name=industrial_maintenance_station%20(1).gif)

.gif?width=400&height=251&name=dual_platen_height_sensors%20(1).gif)